Gallery

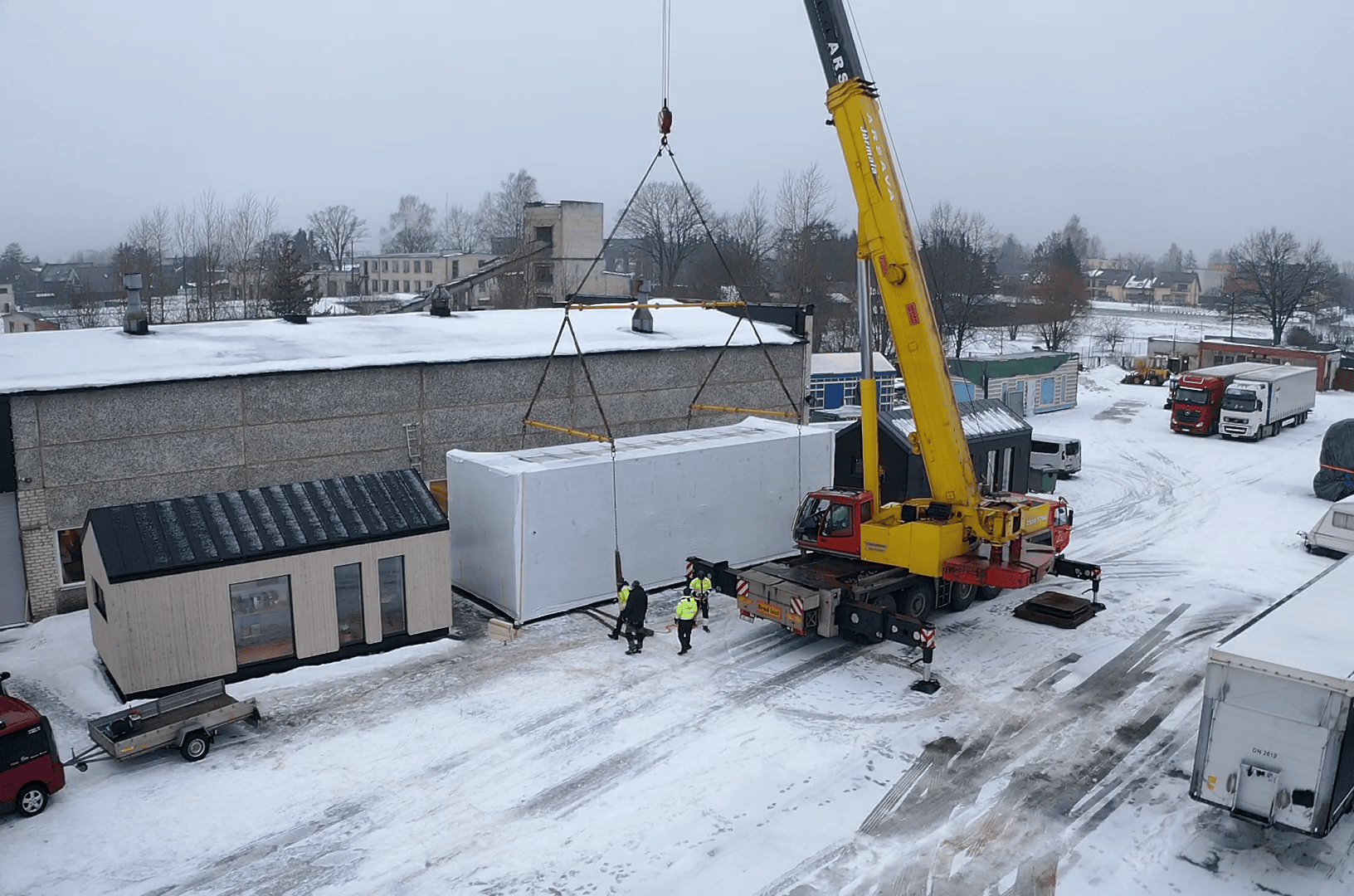

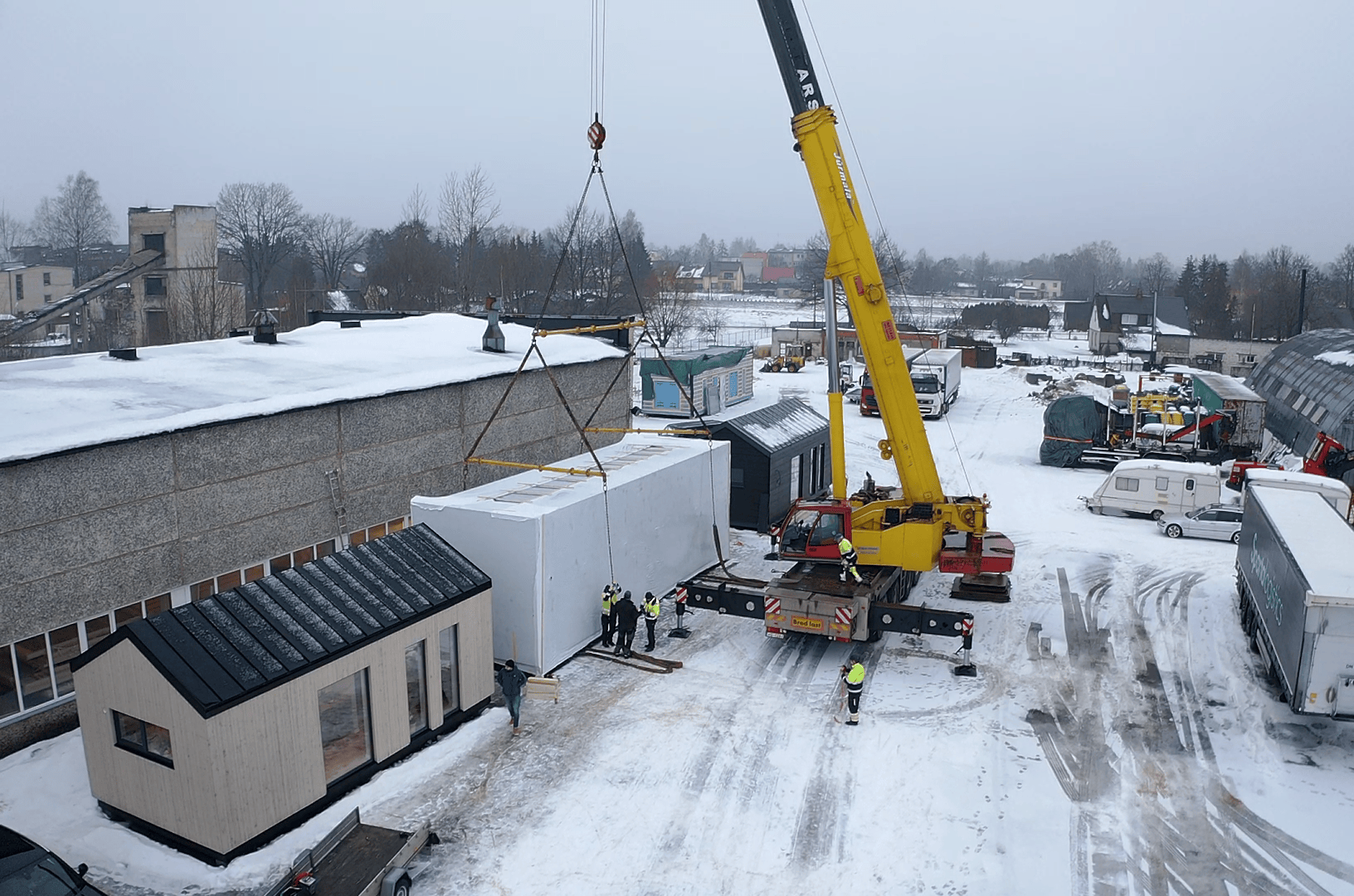

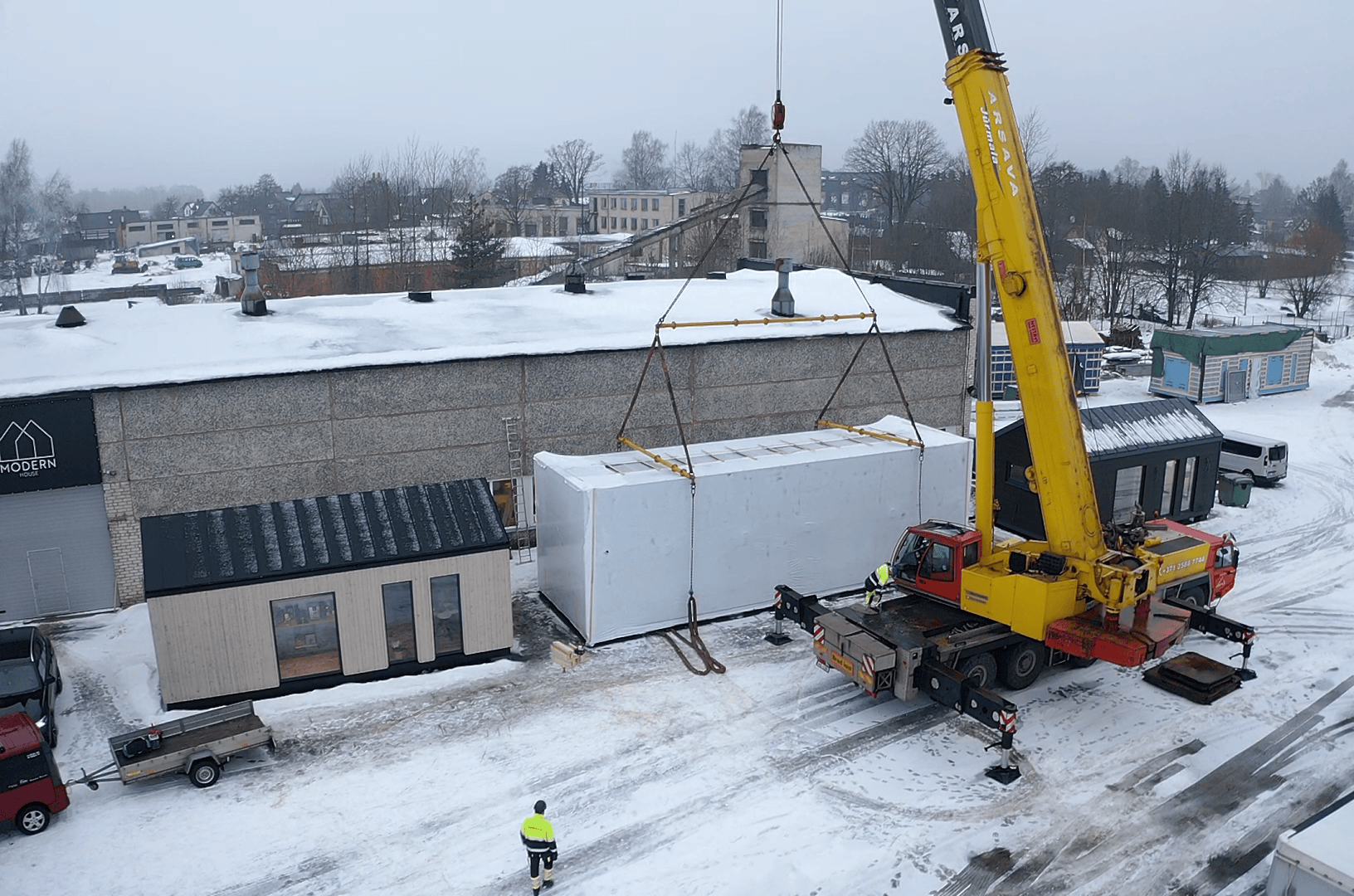

Assembly Process for the Vitolu Street Project

Our priority is to provide clients not only with visual and functional satisfaction but also long-term value by utilizing the most reliable technologies for home sustainability and energy efficiency. We believe that a high-quality construction process enhances the well-being of both the home and its surrounding environment.

Transporting the Visby Module

The Modern House team is delighted and grateful for every client’s trust and choice. This time, our wooden frame module, Visby, was transported to Aluksne!

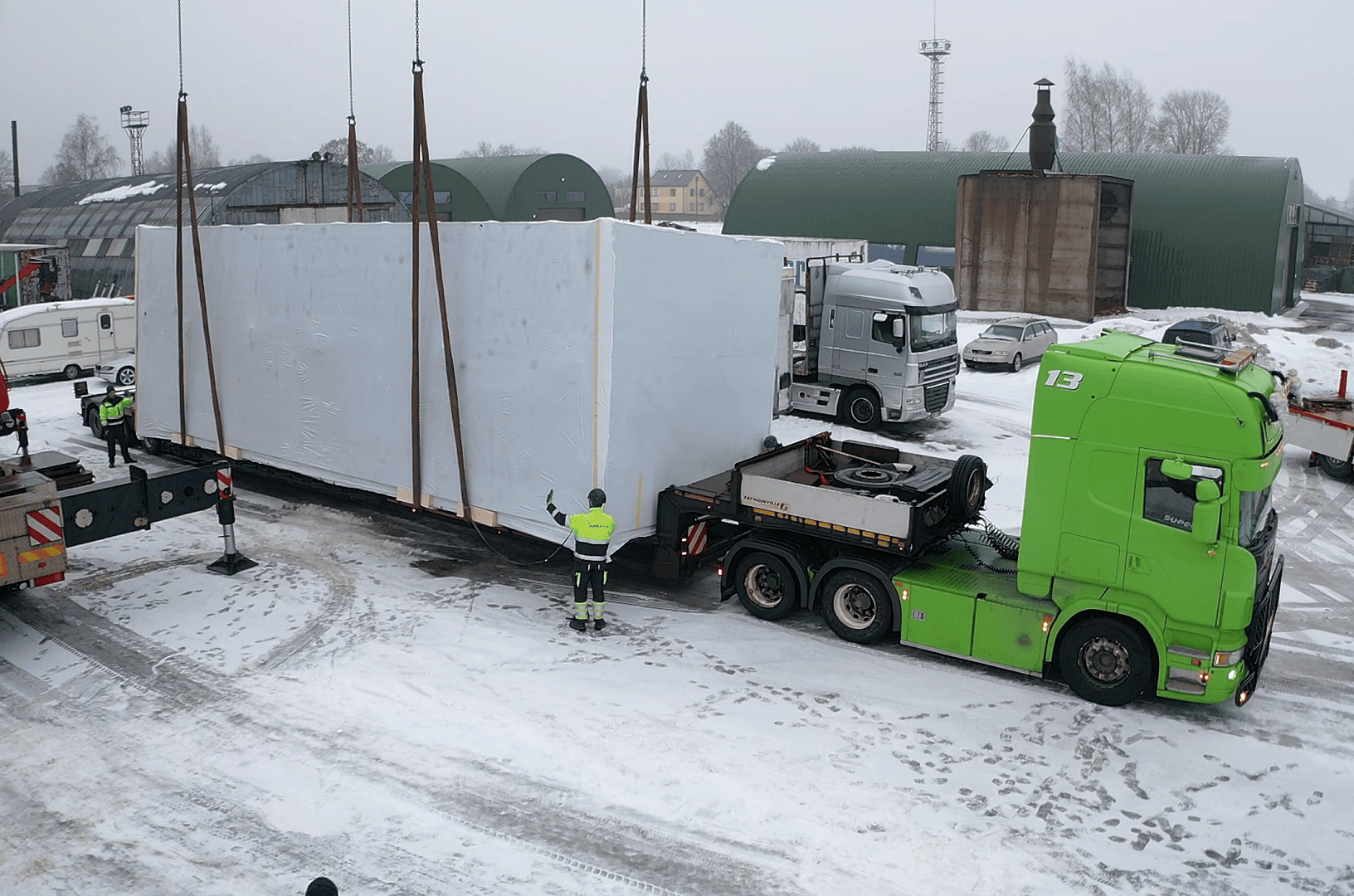

Transporting the Frölunda Module

An open-type cargo platform was used for transporting the modular home. The placement of the building onto the platform and onto the pre-prepared columnar foundations was carried out using a crane.

SKC and Eltpams

SKC is used to ensure sufficient insulation and eliminate air gaps between wooden joints. Eltpams serves as a waterproofing layer, adhered to the concrete with Butyrub. Paroc XSS01 200mm is utilized to seal and insulate the connections between walls and foundations.

Additionally, Siga Fentrim adhesive tapes are applied on the exterior to ensure airtightness, while Siga Rissan is used on the interior for the same purpose.

OSB and Plywood

To enhance the structure’s resistance to deformation, OSB boards are used beneath the drywall finish. These boards also give clients the freedom to personalize their dream home, allowing them to add wall-mounted design elements anywhere in the interior.

Additionally, plywood sheets are used in bathrooms, providing extra stability and enabling secure attachment of shower walls, cabinets, or other fixtures to the walls.